This is probably the most famous of the Mk1 Rally cars, bringing the first International Rally success to Ford in a Lotus Cortina, and mainly driven by Roger Clark.

Ford had rallied Cortinas from the very beginning, and had success with the GT cars, but they couldn’t produce enough power by the mid 1964 season.

Boreham had tried rallying the early Lotus Cortinas with the ‘A’ Frame rear suspension, but these where so unreliable needing constant attention to the back axle that they gave up, until Colin Chapman agreed that the Lotus Cortina should have the more conventional leaf springs.

In February 1965, a batch of new leafspring Lotus Cortinas were built, ahead of the main leafspring production a few months later. These cars were registered in the series KPU 380C to KPU 391C, with some going to Alan Mann Racing, some retained as Press and Management cars, with most (9 cars) were painted in Monaco Red, and they were destined for Boreham for conversion into rally cars.

On the 1st October 1965 the leafspring Lotus Cortina was homolgated to race and rally, and KPU 383C was the car used for the homologation definition.

In the late 1970s, a young Lotus Cortina enthusiast, John Wood, was looking for parts for his everyday family Lotus Cortina, which he also rallied at weekends. He came across a wreck of a Cortina in a field in Yorkshire, but didn’t realize how significant his find was for quite a long time.

This is John’s story of KPU 383C, written after many years of research, building the car, and long discussions with the lads at Boreham who had built and maintained the car in 1965 / 66.

Background to KPU383C

This car was one of the nine Monaco Red Mk 1 Lotus Cortinas built by Boreham for the 1965 rally season over the Spring of 1965. They were the first Lotus Cortinas built by Boreham, as they were the first available with the rear leafspring arrangement. Boreham had previously only supported the GT Cortina, as the Lotus, with its ‘A’ Frame rear suspension, was just too unreliable to be used for rallying.

KPU 383C was originally built for Bo Jungfeldt for the 1965 RAC rally (No 29). Some of the unique features of the car were to Bo’s individual specification, most notable being the floor mounted handbrake from an Anglia. Roger Clark was given the car as his first works drive and won the Welsh International in Dec 1965 with Graham Robson as the navigator.

Spotted at Silverstone in 1965, 383 along with several other Boreham cars attend a testing session. Note the roof spotlight, deleted for the 1966 season.

Roger used the car for the Scottish and Gulf in 1966.

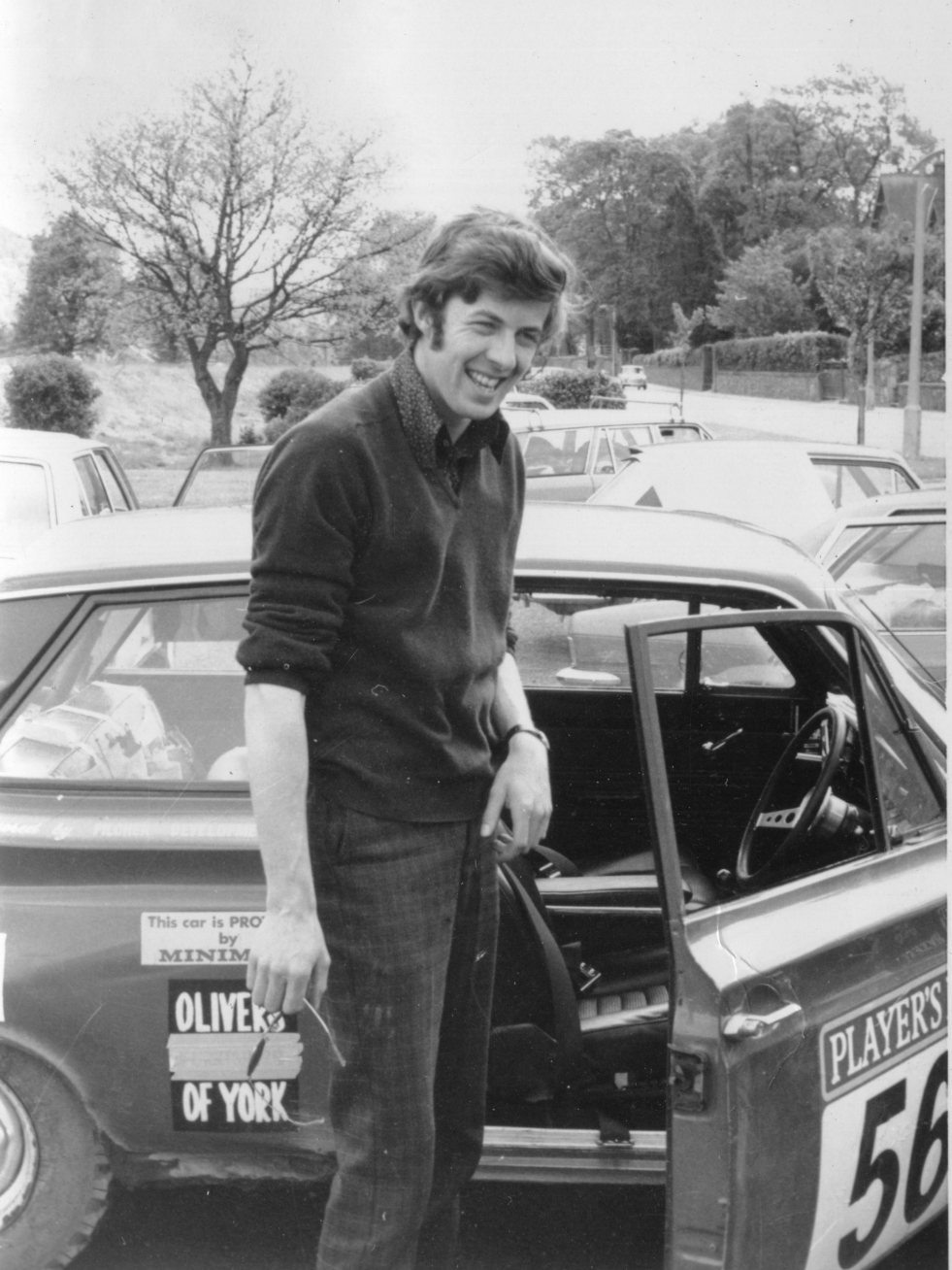

The car finished its works career as an autocross car which Roger used to win the saloon car class in the Players No 6 sponsored 1966 British autocross championship. These shots are stills taken from a film of a couple of the races.

383 was then sold on in 1967 as an unregistered rolling shell to a regular buyer of works bits in Yorkshire and was immediately sold on to Bob Pilcher, for £100 !!

It was still carrying its original number plates but the registration had been surrendered by Boreham. It was re-registered with a local number (HYG 52C) and continued to be rallied until the mid ‘70s competing in many national and international rallies including the Scottish for four consecutive years.

This is how Bob bought the car.

Restoration with a pick-axe; An unusual approach today.

When Bob bought the car it’s pretty obvious from the photos above that it was well used and tired, but then he competed in the car for another few years!

Jim Clark used to run the car with Bob, and he kindly sent in (March 2016) a couple of photos of the car in serious rally mode.

The 1969 Scottish Rally:

The 1971 Scottish:

And the 1972 Scottish:

The car had obviously worked incredibly hard in it’s 8 year career as a rally car and rallycross car, and at the end of that time it was a battered relic and was virtually given away, as it was too far gone to use. It ended up in a field near Pickering with no wheels and just rotting away.

I Bought a Wreck

I was rebuilding my 1965 (all steel) Lotus and wanted to find some alloy panels, and a work colleague introduced me to a friend who had an old rally car with alloy panels. So in 1978 I went to view the (surprisingly) red car and bought it; for the price of a couple of tyres!

He had bought it with the intention of using it for a bit of rallying but it was so rotten that he gave up the idea. When I first saw the car, it was sat in a wet field, on its floor. It was painted plain red and was the most battered Cortina I had ever seen, not just accidents and rust but fatigue cracks and sheer devastation. The chassis rails were completely flattened to what was left of the floor. It was impossible to jack up and my feet went through the floor when I climbed inside. The springs were poking through the rear floor and the strut tops had broken out preventing the bonnet closing.

Only the engine and gearbox were missing although the interior was catastrophic. I dismantled everything on site leaving just the bare shell for a later trip. When the attempt was made to lift the shell onto a truck, the floor stayed behind on the ground and the rest folded up across the roof. It was immediately obvious that the shell couldn’t be re-used.

The car remained in ‘kit form’ for the next two years until I nearly crashed my everyday family Mk 1 Lotus Cortina, HCS 56D on the 1981 Red Rose Rally, after which I decided another more expendable car should be built for rallying. So I stated to rebuild the spare ‘ wreck’ car. The alloy panels were re-used on HSC and I competed in the 1982 Lombard RAC Golden 50 rally in that recently restored standard Lotus Cortina. Following the experience on that event, of competing against ex-works cars, I decided that I needed to find a works Cortina. Many months of searching began but to no avail.

When stripping down the red car, there was mystery after mystery, and peculiar fittings were ignorantly put aside, but never thrown away. It was not until I saw a film of the 1965 Acropolis Rally at a Yorkshire pub meet (thanks to Jeff Fenton), that I began to wonder about some of the cars peculiarities which were surprisingly similar to the works cars in the films. And they were red Lotus Cortinas being rallied! This set me off on a determined effort to trace the missing years of the cars history.

After many months I finally tracked down a previous owner who lit up the jackpot lights for me, “Oh yes” he said “its Roger Clarks ex-works car, KPU 383 C….I collapsed onto a chair, I couldn’t believe my ears. The story then unfolded.

I dug out a copy of Clark’s book “Sideways to Victory” and there it was as his wedding car of all things. This picture removed all doubts as to the car’s authenticity.

The bonnet clips and the screws for the rally plates were still there. One interesting point with bonnet clips, I have checked a number of rally car photos and all the works rally cars have them fitted in slightly different positions. It therefore seems possible to identify a works rally car by the position of the clips.

The only annoying thing about discovering the car’s past history was the colour. There was no public domain knowledge at the time that suggested there were other than white with a green stripe Lotus Cortinas so this curiously red one was to remain an uninteresting anomaly for the next few years. I knew when I stripped it that the car had only ever been red, but I didn’t think any original Lotus was anything but white and green – so that’s what I painted it; and then of course had to re-paint it red again.

So a review of the restoration (now white and green) was called for. Fortunately, as a hoarder I had thrown nothing away and so the task began. First problem was that HSC 56D had the alloy panels so both cars had to be worked on at the same time since HSC was the current family car.

An enormous amount of time was spent tracing the history of the car and the people who had been involved with her. Visits to Boreham staff and Roger Clarks mechanics revealed a wealth of information and original parts from 383 which had been retained as souvenirs including the Heuer Watches, Rogers seats and helmet boxes. The story of the watches is most amusing. The Boreham rally engineer responsible for building the car in 1965 was impressed enough with the restoration that he revealed he had the original Heuer watches and was prepared to re-unite them with the car. He wound them up to check they worked but when parcelled up for postage the package was clearly ticking. In those days of IRA activity a ticking parcel was not a good idea to send by post so there was a delay of 8 days before they could be sent.

KPU 383C re-emerged in 1984 in correct Monaco Red livery and was regularly used on events run by the HRCR in its early days.

Roger Clark had used the car for his wedding, so John using it for a family picnic was quite normal!

A fine gathering of ex-works Lotus Cortinas.

My ultimate rally experience was fulfilled by 383 when I was invited to enter the 1987 Norwegian Viking Historic rally. The catch, if you would call it that, was that they wanted Trond Schea (many times Norwegian Champion) to drive. Well there wasn’t much to think about, this was the chance of a lifetime and I agreed enthusiastically. Ford sponsored me to the tune of a new Limited Slip Diff! Over the three day event, 383 performed perfectly and we won best Ford driver (ahead of Bengt Soderstrom in NVW 239C). To be driven by a world class driver in my own car was an unforgettable experience and I had achieved his ambition to compete in an international rally.

I had enjoyed my time with 383 immensely and when an offer came from TWR (later Arrows F1) owner Tom Walkinshaw, it was irresistible. 383 was not seen again in public until the auction of the TWR collection in 2003. Reassuringly it was exactly (apart from new tyres) as I had handed it over – thankfully no one had interfered with the genuine patina that was (and still is) a feature of much of the car. The car was sold to a gentleman in Japan.

Below, Tom Walkinshaw’s collection of ‘Clark’ cars. Roger Clark’s rally car, Jim Clark’s road car and Jim Clark’s Championship winning race car.

Some Restoration Notes

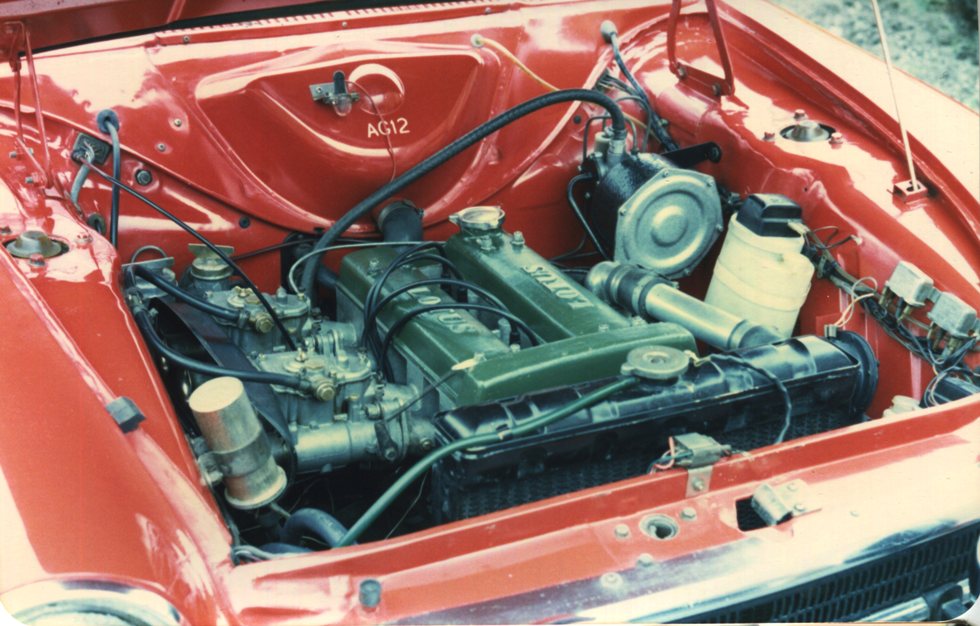

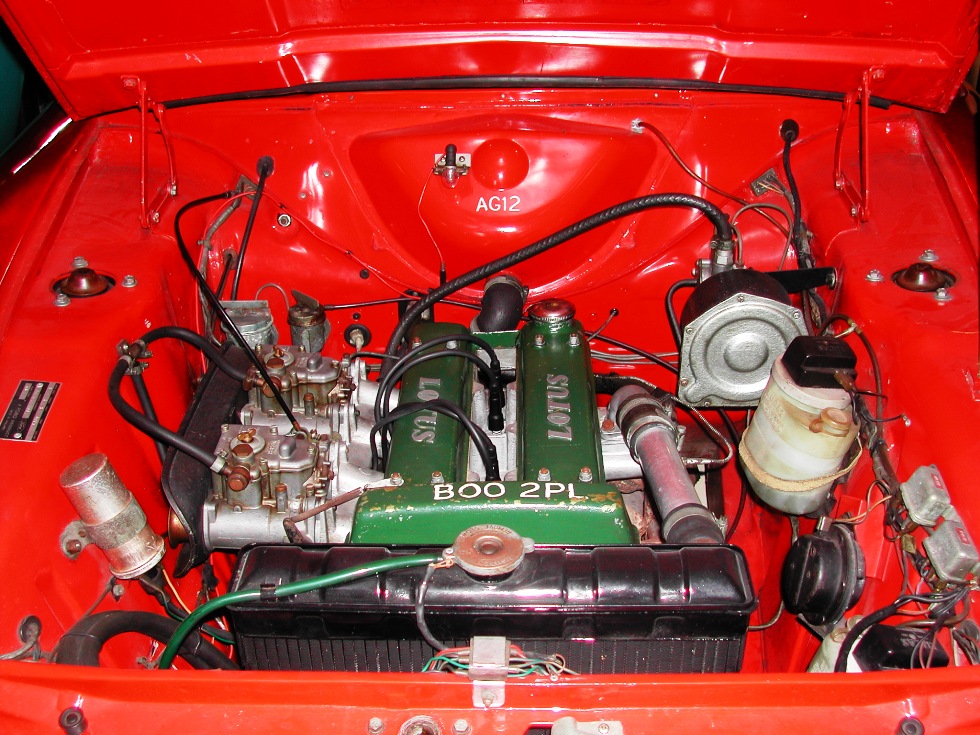

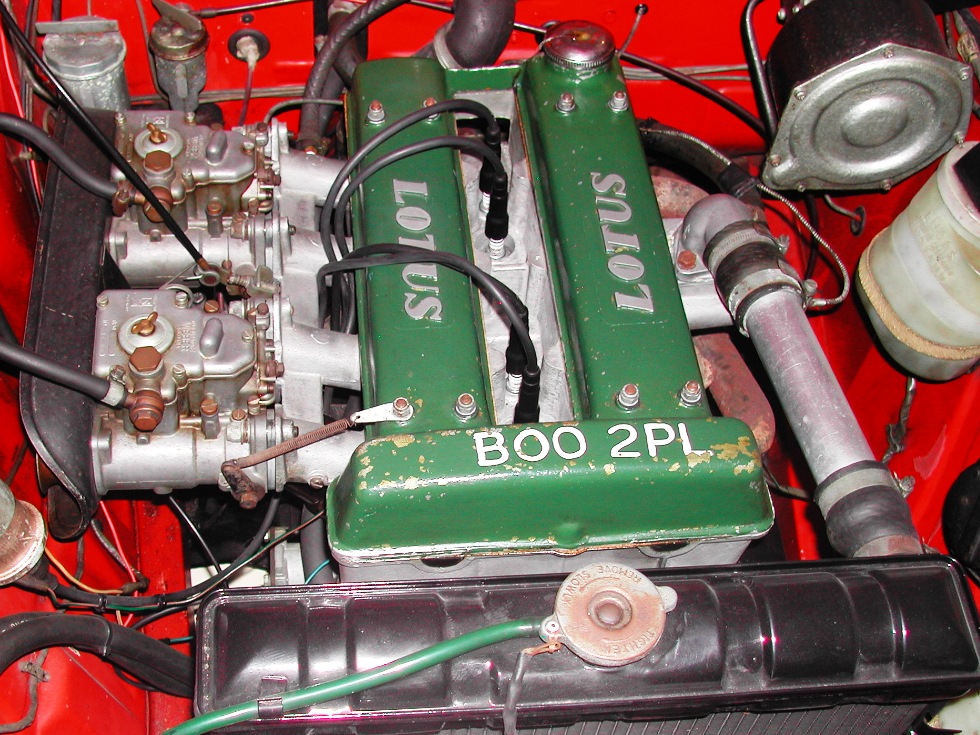

The engine was rebuilt to approximately BRM phase 2 specifications except for the cams which stayed as standard initially. The valves were ‘sprint’ size with port throats opened out and profiled to suit. Inlet and exhaust ports were enlarged, polished and matched to the carbs and manifold respectively. Compression ratio was 11.5 to 1 and the pistons had large valve cutouts to enable higher lift cams to be fitted at a later date. In this specification it developed around 125 bhp.

Nearly everything under the bonnet is re-positioned on the works cars to improve accessibility. The solenoid is on the bulkhead, the coil high up on the inner wing which in turn means there is no air trunking. Other additional features included electric washers, relays for spot and fog lamps and an additional wiring loom. The engine cross member is a special made for works cars only and resembles an export type.

x

x

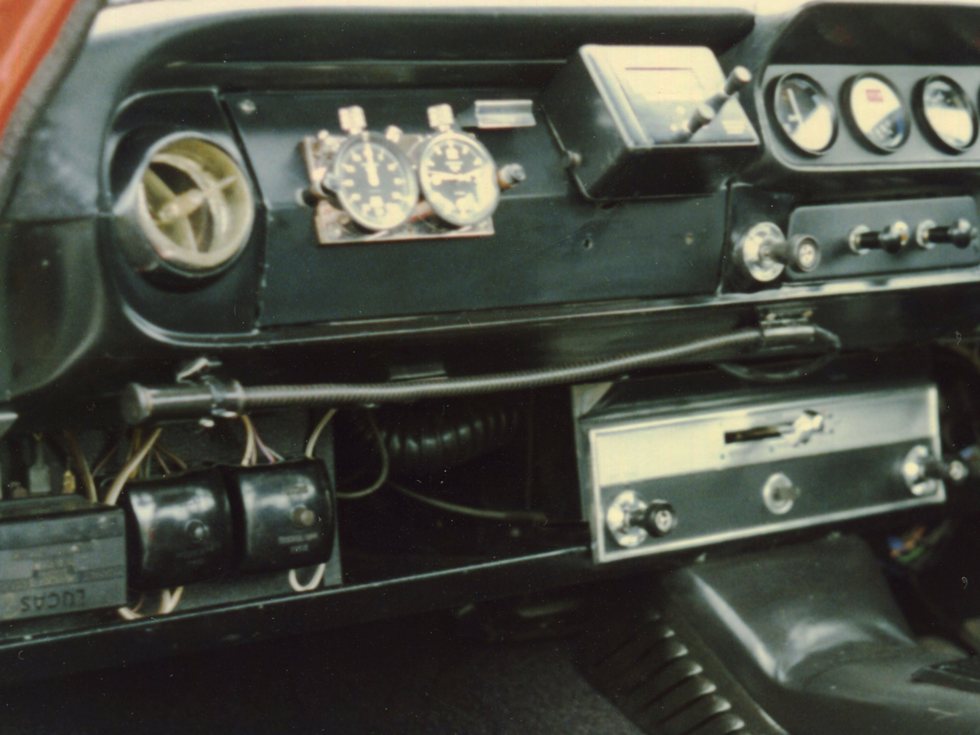

Inside the car the most notable difference was the dash fascia which is matt black, and 383 appears to be the only one I could identify with this feature. There are two fuel gauges (twin tanks) and the oil and water gauges are combined as per the pre-aeroflow Lotus Cortina.

The navigator’s instruments were a Halda twinmaster and twin Heuer stop watches. The cars were fitted with an estate petrol tank, Stuart Warner fuel pumps and variable speed wiper control (as fitted to Corsair 1500 and Zephyr).

Bodywork

Externally apart from the colour, the non standard fittings include boot/bonnetclips, external boot hinges, petrol fillers on back scuttle and additional jacking points on centre outrigger for “quicklift” VW type jack.

A roof mounted spot light had been fitted in 1965, and the regulations changed for 1966 so a small plate was pop-riveted over the hole left by the removal of the spot light.

Works Petrol Tank Variations

The somewhat small 8 gallon tank was generally considered to give inadequate range to the more highly tuned works Cortinas. Consumption dropped to below 10 mpg on rallies with group 2 spec cars. The less highly tuned ‘safari’ cars needed extra capacity to cope with the long distances between service halts.

This led to the works and many private concerns fitting twin tanks to extend the range. The twin tank set-ups appear to have been used only on Rally cars and not racing machines which opted for a single custom built rectangular aluminium tank.

As far as I can gather the first arrangement to appear was fitted to G.T.’s for the 63/64 season. These used the standard tank in the floor but turned though 180° with the filler neck extended to reach the back scuttle. The second tank used was a Mkl estate tank mounted on a tubular frame behind the back seat. The filler pipe was moved so that the cap came through the back scuttle on the R.H. side symmetrically to the lower tank filler on the L.H. side.

Filler pipes appear to have been manufactured specially but used the same caps and body sealing grommets. Whilst the high level filler arrangement gave good access it had some disadvantages. Firstly, the boot lid would not open without striking the caps, this was solved by fitting Anglia hinges on the outside. Secondly, access to the pipe and gauge connections on the lower tank was difficult and some cars had the lower valance partly or wholly cut away to help.

Two other arrangements overcame this latter problem by leaving the bottom tank in the conventional position. The top tank then retained the right hand filler or alternatively the top tank filler was re-positioned centrally on the scuttle.

The central top tank filler was the type that Ford sold through their Rally’s part department and continued through to Mkll days.

A number of other modifications also went hand in hand with the twin tanks:

Instruments

Two fuel gauges were fitted. To accommodate the extra one, the water and oil gauges were combined as per the early type gauge. (Aeroflow cars only).

Petrol Pumps

Electric pumps were fitted but the precise arrangements are still not clear.

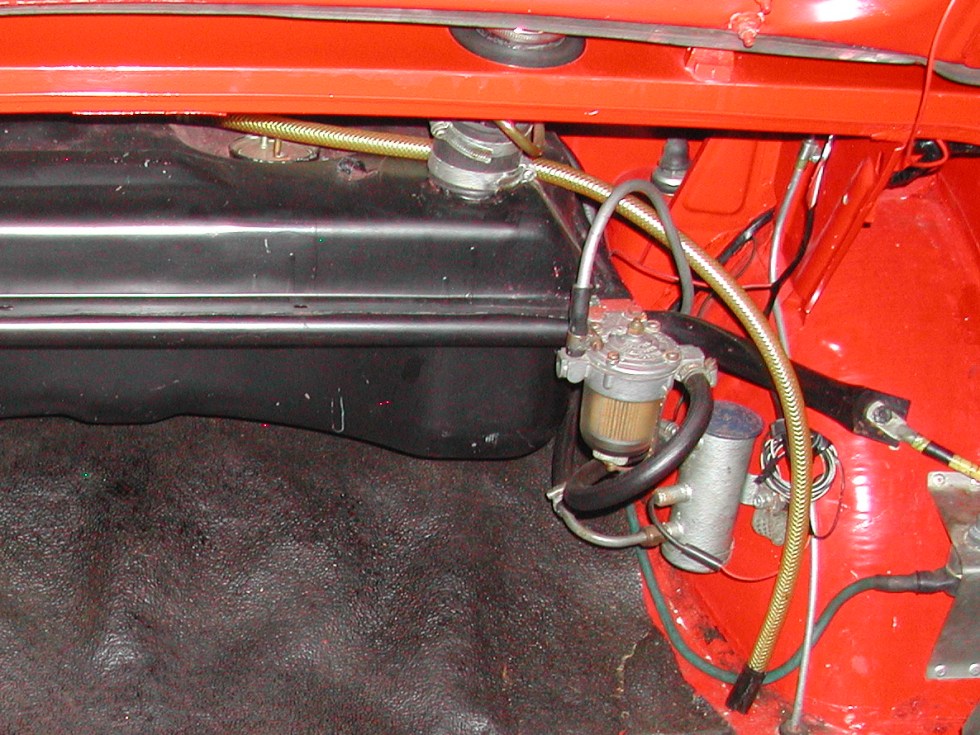

Stewart Warner petrol pumps were used, some had two, others one. They were mounted on the RH side of the top tank.

Filter / Regulator

These were fitted, one per pump to control the fuel pressure. They were in fact what are now known as ‘Filter Kings’ but the idea originated on Alfa Romeo cars to which they are a standard fitting.

Wiring

The electric pumps and twin tank gauges required additional wiring. Custom built wiring looms were fitted in all the works rally cars. Many cars were rewired using black loom tape to identify the modified wiring looms.

All the competing works rally cars were tailored to suit their crews and to some extent the actual events. Two cars were, therefore, seldom identical except possibly the two practice cars.

Other Differences

The car’s first event was the 1965 RAC when it was driven by Bo Ljungfeldt, which it failed to finish due to diff failure. Photos of the car appeared in the Autosport preview of the 1965 RAC and included a full interior view. This authenticates many of the “that’s not original” and “can’t possibly be correct” fittings!

The most obvious feature is a floor mounted handbrake squeezed in between the seat and centre console. The other extraordinary feature is the mysterious rally plate screws on the boot and bonnet. The pictures show these to be present on the car as new from Boreham; This can only indicate these panels were secondhand and had come off one of the works GT’s in the XXX DOO series which had been displaced by the Lotus’.