This section forms the basis of the definition of the Mk1 Lotus Cortina, examining it’s Identity and Statistics, Timeline and Major Features as well as the detailed analysis of Originality across the different variants for the car

The Lotus Cortina Is Born

It is quite amazing that in a few months Lotus managed to design and put into production a considerable number of changes to the standard Cortina, and of course, convey to Ford the changes required for them to make to the bodyshell. And have the factory at Cheshunt extended to provide the facility to build the car! Graham Arnold used to say that Lotus spent the same amount designing and putting into production the Lotus Elan as Ford did designing and putting into production the bumpers of the Mk 1 Cortina, and looking at how quickly the Lotus Cortina was developed, by only a handful of people, he was probably right.

In summary, the changes to the Cortina designed by Lotus were:

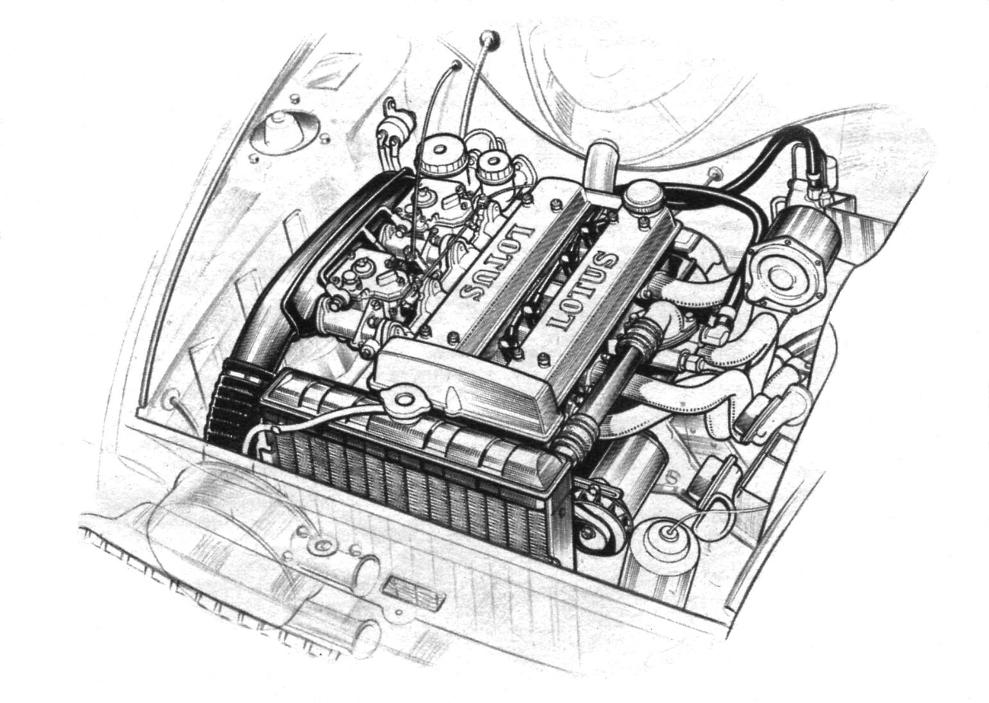

The Twincam engine was mated to the Elan close ratio gearbox, which had an aluminium tailpiece, remote and bell housing to reduce weight. The carburettors obtained cold air via an air cleaner in the nose of the car, and the engine was cooled by a larger capacity radiator. The propshaft was one piece with the main tube diameter of 3 inches and the ends swaged to take standard production UJs.

The rear suspension was fundamentally redesigned using vertical coil over damper instead of leaf springs, with the axle located by a wide ‘A Frame’ beneath trailing radius arms, a design taken from the Lotus Seven. The rear suspension was lower than the standard car. An aluminium differential nose housing was used to reduce un-sprung weight.

The front suspension was redesigned using shortened spring and McPherson strut with heavier damping properties, fractionally longer forged (rather than pressed) track control arms to eliminate wheel camber, and a heavier duty anti-roll bar some half inch longer at the ends bar to reduce castor. Shorter and straight steering arms were employed to effectively give higher steering gearing, whilst reducing the Ackermann angle. A 15 inch steering wheel gave a more responsive feel to the steering. A new high-geared steering box assembly reduced the overall gearing by 12%.

5.5 inch steel wheels were fitted with 6.00 x 13 inch cross ply tyres.

Girling brakes were employed working on 9.50 inch discs at the front and 9 x 1.75 inch drums at the rear, operated by a remote servo running at 2.04 : 1 ratio mounted at the rear of the nearside inner front wing.

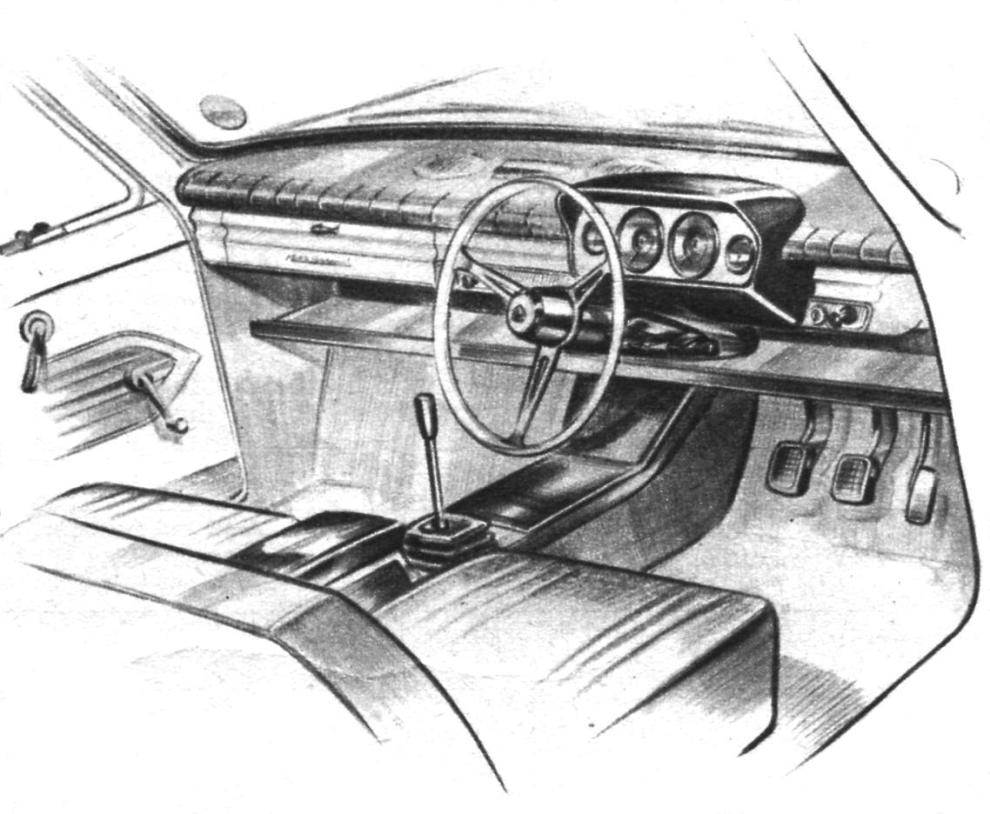

For the interior, special seats were developed on the standard frames just for the Lotus, which provided more lateral support, greater rake and more comfort. A centre console with elbow rest / cubby box was installed between the seats. Dunlop ‘Hytone’ moulded rubber mats were fitted. Four instruments were contained in the dash pod, with a 140mph speedometer, an 8000rpm rev counter, a fuel gauge and a split oil pressure / water temperature gauge, all similar to the new Elan instrumentation. A studded 15 inch woodrim steering wheel with Lotus hornpush was fitted onto a steering column of reduced length, to increase arm reach, and a concave top pear shaped wood gearknob completed the Lotus specification inside. The metalwork inside the cabin was the same as the exterior colour…Ermine White.

The bodyshell used the panels from the Type 74 Cortina Saloon 2 door deluxe Floor Change, built up with enhancements to make it stronger, lighter and to accommodate changes to specification made above. The shells were built in batches in Dagenham outside the standard production line, as so many variations were built into the shells at a very early stage of manufacture that couldn’t have been ‘added’ to a standard shell once the shell was completed. The shells, complete with panels, were part assembled at Dagenham with all the parts common to other Cortinas (headlining, glass, lights, heater, wiper motor, door locks, etc.). They were then delivered to Cheshunt for final assembly using the Lotus specific components and to have the stripe added.

The enhancements to the bodyshell included:

Aluminium skins for the doors, boot lid and bonnet.

The battery tray moved to the boot.

Tubular members ( King Posts) were added on both sides of the boot between the top of the rear wheel tub and the (former) rear spring shackle mounting points. Another tube runs from the top of the tub to the horizontal sill member immediately behind the front door ‘B’ Post.

A ‘hump’ panel was introduced in the forward boot floor over the differential to accommodate the lower rear suspension.

The ‘saddle’ panels on the chassis rails over the back axle were modified to allow the axle extra movement.

Brackets were installed to take the radius arms and A Frame.

The rear chassis members were double skinned between the old leaf spring mounts (a heavy duty shell feature).

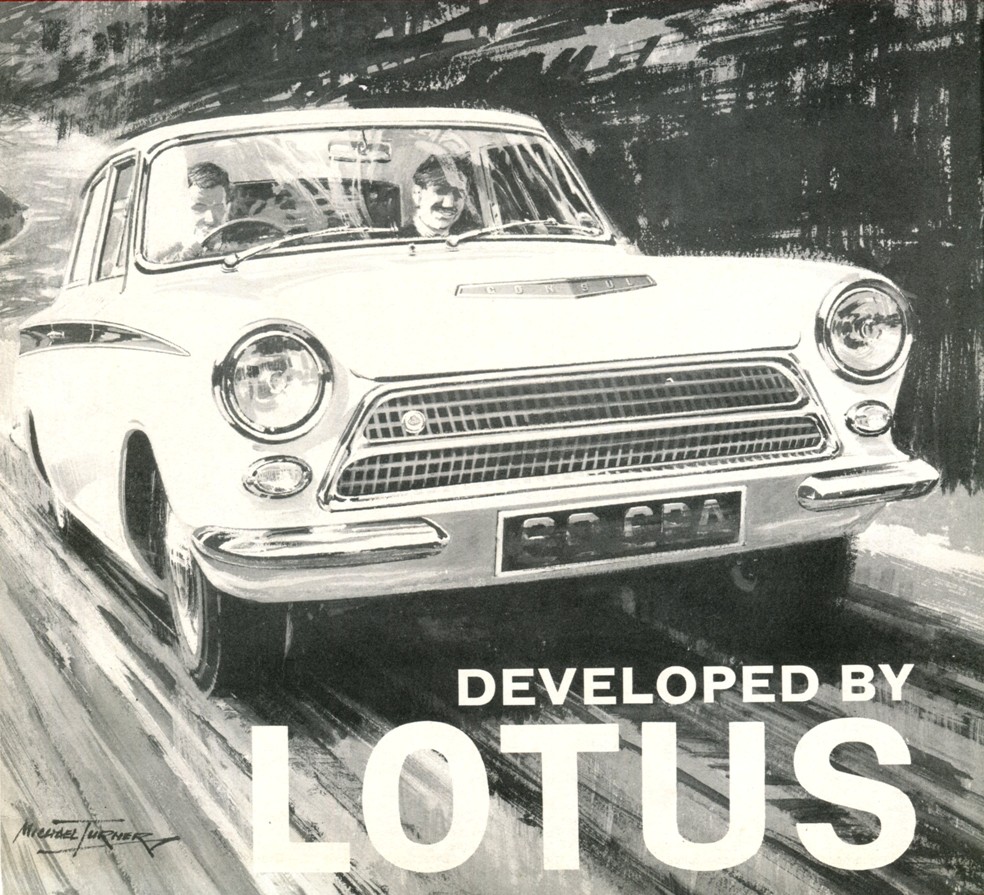

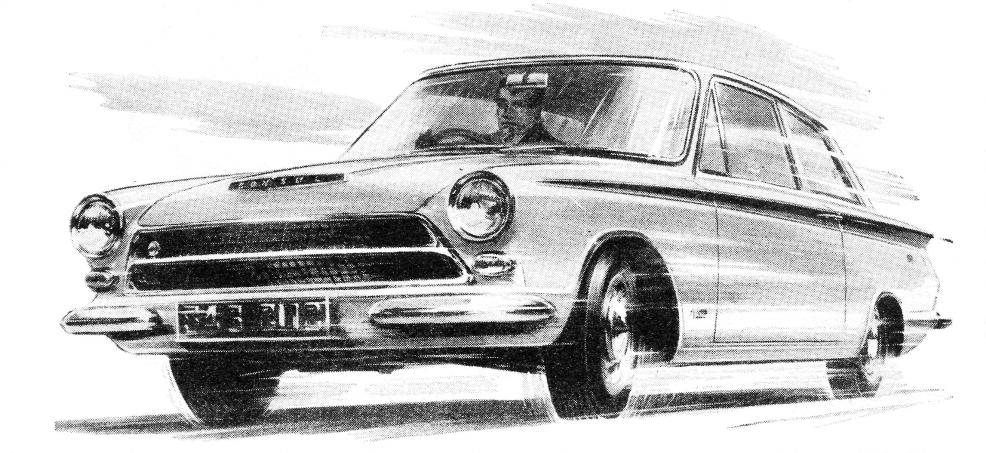

On the outside, the Lotus Cortina was painted in Ermine White with a Sherwood green stripe, sported (painted) Lotus badges on each rear wing and one on the grille, which now had a black infill. Quarter bumpers were fitted to the front, pinched from the back of the Anglia Van!

In January 1963 the Consul Cortina Sports Special was launched to the world, but by the time they were available, they were known by Ford as the Cortina (developed by) Lotus. The Press started to call them the Lotus Cortina, but Ford stuck to having ‘Cortina’ first in all their brochures and manuals.

The fabulous painting by Michael Turner commissioned by Ford that appears on the front of the launch brochure of the Lotus Cortina. That definitely looks like Colin Chapman in the passenger seat, and I like to think he is being driven by Jim Clark. Jimmy did a lot of pre-production testing on both the road and race Lotus Cortinas, and went on to become THE ambassador for the Lotus Cortina, Ford, Lotus and British Motor Sport in the 1960s.