This section describes the 2 door 1600E Cortina. This has been separated out from the 4 door 1600E due to it’s rarety, and due to the similarity between the 2 door shell used for this car and the Lotus.

Introduction to the 1600E 2 door

The 2 door 1600E was produced for export only to European countries, and consequently was only made (as standard) in left hand drive form. However, a ‘small handful’ of right hand drive cars are known to have been made for the few countries in Europe who also required RHD cars, and a few it seems for Ford executives as special commissions. At least one was ordered by an RAF man posted to Germany but who was returning to the UK within a year so wanted the car to be RHD ! And one was bought new in Rhodesia. More on these RHD cars at the end of the section.

The 2 door 1600E was based on the 2 door GT, using a heavy duty shell, with all the 1600E enhancements.

It was introduced shortly after Series 2 production began, sometime around October 1968. It has the same chassis number identification as the GT, being 96 for the 2 door GT.

For the avoidance of doubt, the 4 door 1600E was based on the 4 door GT, with body code 97.

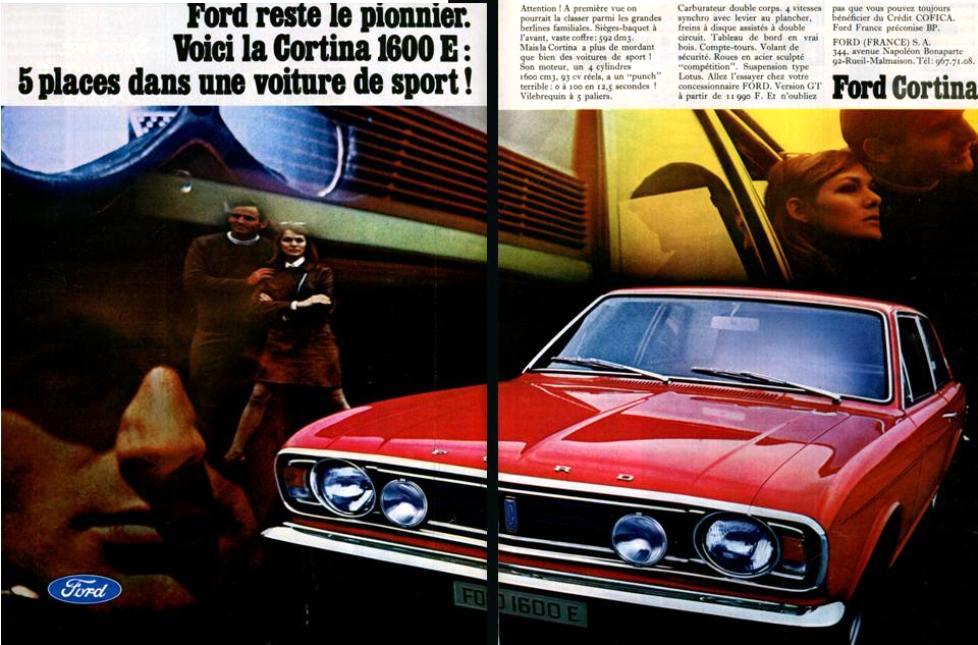

The 2 door 1600E was sold as the ‘luxury’ performance Cortina, alongside the GT, in a specially produced catalogue for Europe. This catalogue was printed for each country is it’s appropriate language. See below, the centrefold of the French catalogue.

The Lotus Cortina was primarily aimed at the UK market, where Lotus and the competition successes of both the Mk1 and Mk2 Lotus were most recognised. In other markets, the marque of Lotus was less well recognised, and the Lotus Cortina sales fared less well. Hence the 2 door 1600E was created to fill a niche in European markets created by lack of Lotus Cortina sales, and of course, the reason it wasn’t sold in the UK as it could have reduced the sales of Lotus Cortinas.

Production

The cars all started life at Dagenham, but in two different forms. Firstly, CKD (Completely Knocked Down) kits were made early in the production of the Series 2 Cortina, and sent to European plants for building. Fully built cars were made at Dagenham from January 1969, well into Series 2 production, until July 1970, one month before the end of Mk2 Cortina production.

The earliest CKD car I’ve seen so far was a project car I had, and that had chassis number starting with CN96HS, which is CKD, 2 door GT, built in November 1968. I’m not sure yet if the November applies to when the kit left Dagenham, or when it left the Netherlands factory, fully built.

2749 2 door cars were made, with 1083 of those being fully built at Dagenham, and presumably this number includes the small number of RHD cars made. The other 1666 were made in component form (CKD) at Dagenham.

Paris Motorshow, 1969. Note the name (Tudor) and the black grille and pinstripe.

Specification

Mechanically, the 2 door used the same components as the 4 door, with the 1600GT engine, the 2000E ratio single rail gearbox, the lowered Lotus suspension and the Lotus brakes.

The 2 door employed the dual braking system (as per LHD 4 door 1600E), with integral master cylinder and servo unit.

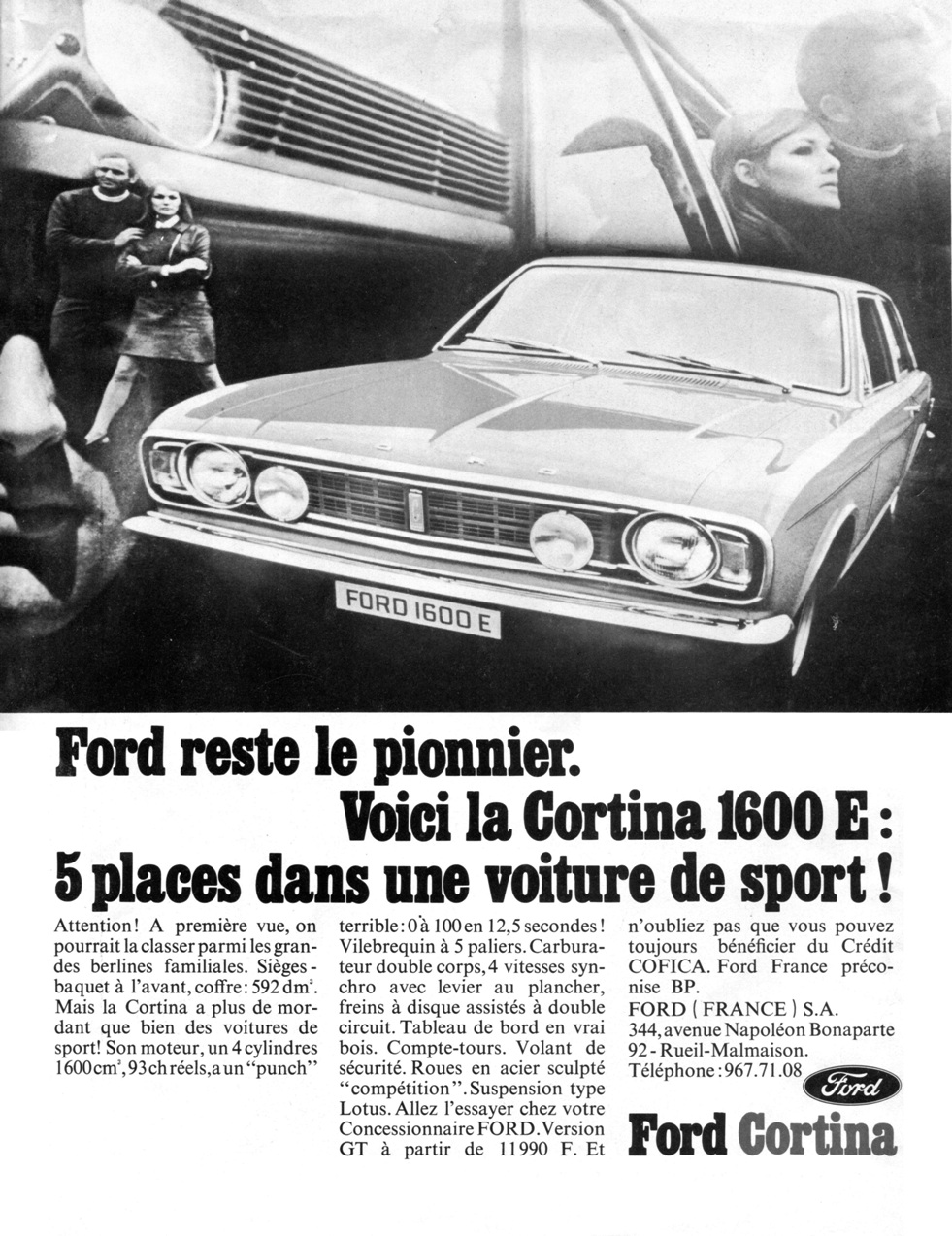

The trim was also the same as the 4 door (Code D234 for the black trim). The carpet was the same deep pile as the 4 door car, and the seats were the familiar Series 2 1600E versions, with tilt / recline front seats and split rear seats with fold down arm rest.

The door and rear panel wood capping was made specifically for the 2 door 1600E.

The ‘safety’ steering wheel was used for most of the cars.

The bodyshell is based on the heavy duty 2 door GT shell, as per the Lotus. This has the re-enforcement panels around the front struts, and the double skinned rear chassis rails at the rear. As for the Lotus, the 4 door 1600E and the earlier GT, the shell had the brackets for the anti-tramp bars. As for the Lotus and 4 door 1600E only, the front wing arches are rolled. The main difference between the 2 door 1600E shell and the Lotus Cortina shell is that the battery tray is mounted under the bonnet in the 1600E, and in the boot in the Lotus. There are a couple of other minor differences such as the water washer bottle (in a cage) on the Lotus replaces the washer ‘bladder’ on hooks on the 1600E. However, the RHD 2 door 1600E also has the Lotus washer bottle!

Changes to Specification

The car was only available in Series 2 form. When launched, the 2 door car had full-chrome Rostyle wheels (of the Series 1 1600E), a black grille, a pin stripe down the side, and a black rear panel.

The full chrome wheels were soon dropped (latest March 1969) replaced by the standard Series 2 1600E Rostyles with chrome centre and painted rim.

For some markets, the pinstripe and black rear panel were deleted, and the black grill replaced by the standard back and silver grill for 1969. The pinstripe and black grill, and presumably the black rear panel certainly carried on in some markets until the end of production. See the photographs for the ‘1,000,000th export Cortina’, taken in July 1970, showing a 2 door 1600E in white being taken to Europe below a helicopter. It has the black grille and pinstripe, and presumably, the black rear panel.

The late models from March 1970 had the all-painted Rostyles, and reversing lights mounted on brackets further in on the rear valance (between the over-riders), as per the 4 door 1600E.

The millionth export Cortina in July 1970 just happened to be a 2 door 1600E.

For publicity of this export achievement, the 2 door 1600E was taken to it’s new owner in Ostend, Belgium, by helicopter. I wonder if this car still exists.

Statistics

At 2749 units made, the 2 door 1600E was the most rare of all the Mk2 Cortinas out of the 1,013, 391 Mk2 Cortinas made. With 57,524 4 door 1600Es, and 4032 Lotus models made, the 2 door 1600E was a very small niche market for Ford UK.

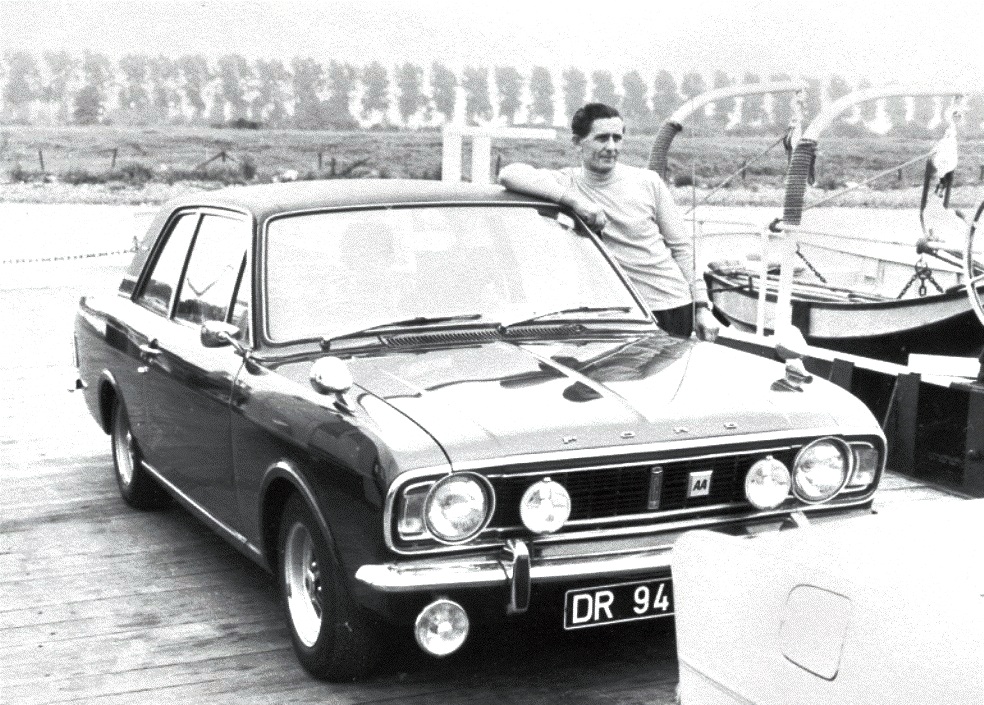

Press photos of the 2 door 1600E, this time showing it with the standard GT grill and no pinstripe. It is believed that this was one of the cars built by a local Ford plant in Europe from a CKD kit, and that some markets, perhaps towards the end of production, dropped the extra cost of the black grill, black panel and pinstripe, as well as adopting painted Rostyle wheels.

My 2 2 door cars, the 1600E and Lotus. The similarities are remarkable, with virtually identical heavy duty shells with rolled arches, Lotus suspension and brakes. The 1600E was delivered new to France, and kept by the same family in their holiday home in Spain for many years. Luckily it was kept in an underground car park out of the Spanish heat, and has survived with all of it’s original panels, chrome, rubbers trim and most of the paint.

The interior is all original with the exception of the 1600E steering wheel. All left hand drive cars had the plastic ‘safety’ wheel, which I quickly replaced with the proper wheel. Note the ignition switch / steering lock, which was standard on many export cars.

The Right Hand Drive 1600E

As mentioned above, very few of the 2 door 1600E cars were made in RHD form, and it seems likely that there were less than 30 made.

The cars that have come to light over the past 25 years are just these 7, and only 2 of them are known to survive. A third car is still on the DVLA website, although it is unknown whether or not it survives.

The cars are:

TLF 794G, CML 30H, CML 238H, CML 620H, CML 627H, DHD 525J and LWT 221H ( ex Zimbabwe 93-981C).

TLF 794G has it’s origins well documented by it’s original owner who contacted me in 2018. That story is below. It is recorded on DVLA, but it hasn’t been on the road since 1983.

CML 238H was an Aubergine coloured car, and was on the road until 2004, but has now disappeared, hopefully tucked away.

CML 627H was a Fern Green car that had been re-painted Black. In around 2005 it was scrapped, but a 2 door left hand drive 1600E was converted to right hand drive, and the identity of CML 627H was going to be put on that. Unfortunately (or fortunately, depending on your point of view) it became public knowledge that the original car had been scrapped, and the converted car could therefor not be registered.

DHD 525J is a Blue Mink car, and is alive and well and currently undergoing a restoration.

LWT 221H is also a Blue Mink car, and is virtually identical to DHD 525J. It was found in Bulawayo, Zimbabwe, registration 93-981C , in 2017, and brought back to the UK by me. It has since undergone a 3000 hour restoration back to factory original specification. It needed a lot of TLC!

Nothing is known of CML 30H or CML 620H.

Why were there so many CML registered cars? CML is a central London registration number, and it seems likely that these special order cars were processed through the Ford Export office and showroom in Oxford Street, London. The 2 door 1600E was really for export only, so it seems quite likely that the Right Hand Drive cars had to be processed via this route.

Right Hand Drive 1600E Specification.

With only two known survivors, identifying the specification from such a small sample may not be correct for all the RHD cars made! But those two are almost identical, being ‘export specification’ right hand drive cars. Both were fully built at Dagenham, both are Blue Mink with Black trim, and the Body Tag plate for the cars is just 1 digit different, despite them being built 3 months apart.

The ‘Export Specification’ is essentially dual circuit brakes, but that has quite an impact in the engine bay. A few territories had the same RHD export specification, including Ireland, Malta and when exported fully built to Rhodesia, New Zealand and Australia (rather than being exported as a kit and built locally).

The dual circuit brakes are fitted with an integral servo, and on a right hand drive car, that is too close to the inlet manifold and carburettor, so the servo and master cylinder have to be mounted on a ‘tower’ (similar to the later Escorts) in order to clear the carburettor.

This in turn which has meant that the battery tray is moved and is now on the left hand side, which in turn displaces the bladder type washer bag on hooks which has has been deleted. It is replaced by a Tudor washer bottle set much further back on the left side inner wing towards the bulkhead. That bottle is the same one as fitted to the Mk2 Lotus Cortina and export LHD Mk1 Lotus Cortina

Both cars also have the opening quarter-lights, and whilst the Zimbabwe car has the standard ignition switch in the dash, DHD 525J has the same steering lock arrangement of many of the LHD 2 door 1600E cars. The Zimbabwe car had the sump-guard and petrol tank guard fitted, which it needed!

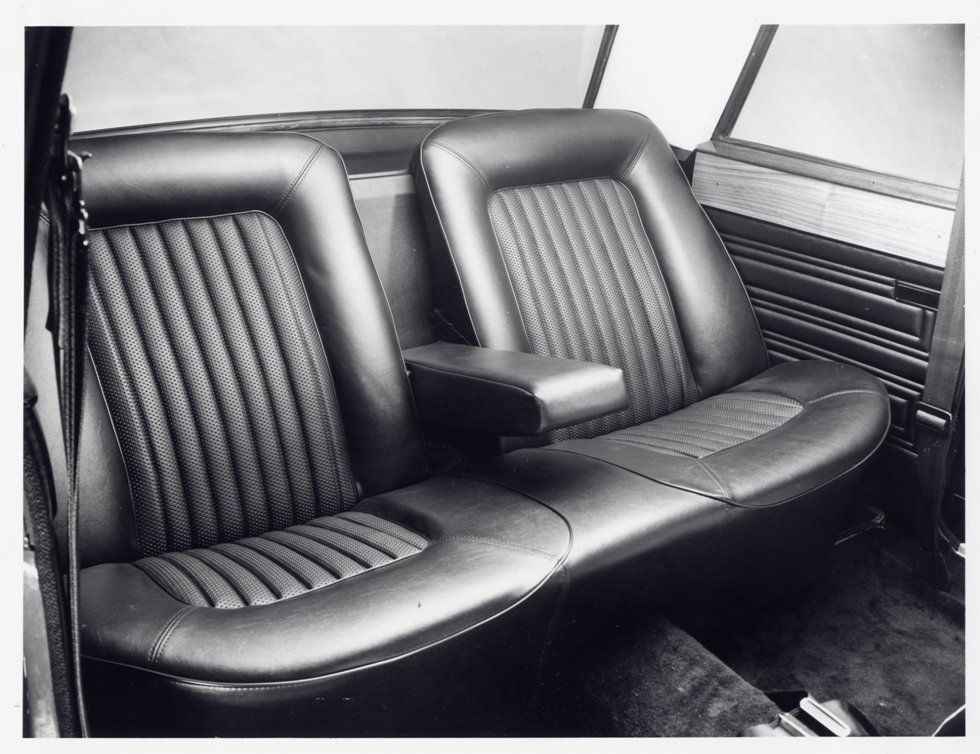

TLF 794G Story

I was contacted in 2018 by the original owner of TLF 794G, Mr Mike Young, and he kindly told me the story of his car, and sent a couple of photos of the car when it was new. These are the only photographs of a right hand drive 2 door 1600E I have seen when the car was new.

Mike was in the RAF stationed in Germany, and being interested in cars (having an Escort GT at the time) visited a nearby Ford dealership in Holland, and tried out a 2 door 1600E (in left hand drive). He liked it! Interestingly, the car had a black headlining.

As he was returning to the UK within a couple of years, he wanted the car in RHD form. He made enquiries at Weilers, the German UK Forces agent, and they processed his order for the car, finished in Anchor Blue with a red pin stripe.

He had to go to London to pick the car up at the Ford Export showroom in Oxford Street, where it had been registered as TLF 794G. Mike paid £850 for the car as it was tax free, saving nearly £250 on the new car price.

Mike then drove the car back over to Germany, and took this photograph as he was crossing the Alps on his way to Italy when the odometer went over 1000 miles:

The car was registered in Germany where it was used daily. He decided to give the car a good clean one day and took the back seat out, and found a build sheet for the car with his name on it. The RHD 2 door 1600E was only built to special order. Mike returned to the UK as planned, running the car for a while, and sold it on to another RAF man in 1972 / 73. The car registration number is still on the DVLA site, but has not been on the road for more than 30 years, so has probably now gone.

This photo was taken on a ferry in Germany

LWT 221 (Zimbabwe 93-981C) Story

In November 2017 a rather tatty looking Cortina came up for sale on one of the Facebook forums, looking very unloved. To make matters worse, the car was in Bulawayo in Zimbabwe, not the easiest place from which to get a car exported. I glossed over it thinking it was going to stay there indefinitely, until I noticed the small 1600E badges on the rear roof pillars.

I asked to see more photos and a photo of the chassis plate and body plate, and sure enough, it had the identification of an original 2 door right hand drive 1600E. Looking through the photos sent over, it also had all the attributes of a real 1600E, including the rolled front arches, the same as the Lotus, something that wouldn’t be faked. For me, this was finding the Holy Grail, so I had to try and buy it and get it shipped back to the UK.

It took 5 months with a lot of help from a chap in the UK who imports cars from South Africa, and his agent in Johannesburg. And a few £££s !! It was still a trek to get the car from Bulawayo in Zimbabwe to Johannesburg in South Africa, being some 900kms apart, with one of Africa’s most notorious border crossings to get through. But in April 2018 the car was back in the UK for the first time since 1970. It was completely stripped, and work started on finding the parts required to restore the car, alongside hunting for a bodyshop who could restore the shell to a high, factory-original standard in a reasonable time frame.

The car was fully built at Dagenham in April 1970, and was painted in Blue Mink. At some time, quite a long time ago by the looks of things, it was re-painted in a light Blue colour. It was always going to be re-finished in it’s original Blue Mink colour of course!. Both the chassis plate and the oblong body tag confirm that this is an original RHD 2 door 1600E, and in fact was the 18th one built.

The car was remarkably original and complete, although much of the trim and wiring had been eaten by rats and monkeys, and the chrome trim was mainly wrecked! It still had it’s original engine and running gear, and the body shell was in very good condition (considering it’s background) with very little of the rot that an original UK car of this age would have. On the downside, it did have a fair bit of rock damage behind the front wheels, and the front floors were pretty rotten where the rain had got in over the years. And just about every panel, including the roof, was dented and required a fair bit of work to get straightened out .

All the parts were found and the sub-assemblies restored whilst the bodyshell was being restored, and in December the shell was completed, all the large sub-assemblies restored, and work started putting the car back together.

After 3 years and some 3000 hours the car is now restored back to factory original specification. A lot of care was taken to save as much fabric as possible of the car due to its rarity, and the bodyshell retained all of it’s original outer panels except for its bonnet, front valance and two outer sills. They were all just too bent to fix! This is what it looked like in Bulawayo…

Back in the UK in the summer of 2018, fully stripped out and waiting to go off to the bodyshop to be restored.

The shell was in the bodyshop for a year, with the first 4 months repairing the metalwork. Once all the panels had been repaired, and perfect clearances and panel alignment had been achieved, it went though the standard modern sequence of restoration and paint preparation / painting. That is, epoxy primer, final metalwork adjustments and panel beating, re-epoxy primer, polyester primer, levelling, high-build primer, colour coat and finally, clear coat. In all some 950 hours were spent on restoring the bodyshell.

The rolling shell was back home in December 2019, and work started on re-building the car with the restored sub-assemblies and new parts. This is quite a slow process as every component, nut and bolt has to be up to the standard of the finish of the shell !! It took a year to complete the re-assembly, although of course that was interrupted with the Pandemic, making some parts very hard to find for a while.

It took 5 months to get the car registered with the DVLA, but in April 2021 she was nearly ready to go back on the road in the UK for the first time in 51 years. Just a few more small bits to find, but some of those are proving to be elusive!