INTRODUCTION

This section seeks to pull together the information required to identify a Lotus Cortina (from the Identification Plate and Body Tag), together with identifying the volumes of Mk1 Lotus Cortinas made.

This is presented from information already provided in publications, especially the Ford Cortina Parts List, 1962 – 1966, and information that has been published by the LCR, for example, the register of cars published in the late 1990s.

I have also collected information from forums and other publications, where such information has been verified.

It should be noted that just because a car has the correct Identification as described below, it is not proof that the car is a genuine Lotus Cortina. Identification plates are only riveted onto the shell, and numbers can easily be stamped into the shell.

If the car doesn’t have the right verification that it is a genuine Lotus Cortina, then you really have to know what you are doing before parting with your cash!

Note that some folks get confused…is the Lotus Cortina a Lotus or a Ford?

It is most definitely a Ford, largely designed and built at Ford’s plant at Dagenham, using mainly Ford parts or Ford sub-contractor parts.

The car has a Ford Identification plate.

The confusion arises as the car is commonly called the ‘Lotus Cortina’. Ford never called it that, but always had it as the Cortina (modified by) Lotus. But the press and indeed Lotus preferred the term Lotus Cortina, and that has stuck. And of course, the car had it’s final assembly at Lotus, and Lotus even gave it an identification of the ‘Type 28’, and that gave it the kudos needed to make a special car very special indeed!

But looking at the identification information below, it is all standard Ford construct.

THE IDENTIFICATION PLATE

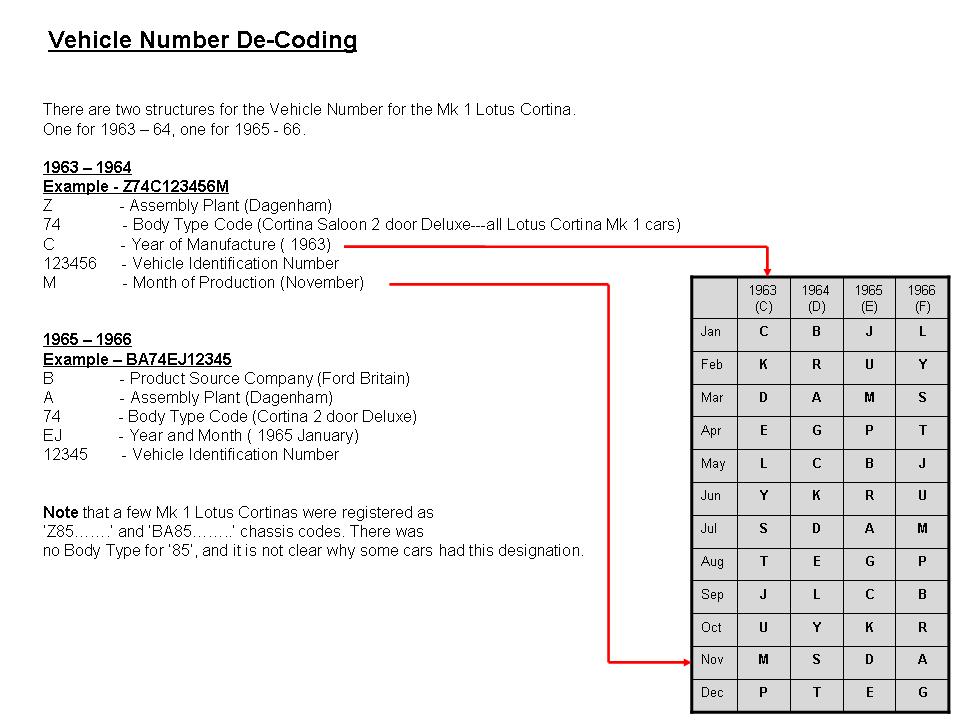

There were two versions of the Ford Identification Plate used for Lotus Cortinas.

The first is a square plate with the information set across the plate to give the square a diamond appearance in the car, used for the 1963 and 1964 production years.

The second is an oblong plate, used for the 1965 and 1966 production years.

The main information on the plate is the Vehicle Number. This uniquely identifies each car, and is also the number stamped onto the inner wing in front of the right side strut top mounting area. It is the number by which the car is identified by the authorities (DVLA and Police in the UK), and it cannot be changed for a vehicle (unless it contained errors when it was being created, which did happen!)

The Identification Plate also contains other information, which identifies the specification of the car as built.

For the early plate, there are only 3 pieces of other information, and they are:

Model Number

125E (Ford designation for the Lotus Cortina – Twincam

Paint Code

Usually BA for Ermine White

Trim Combination Number

Always ‘A875’

There is a little more information on the later plate, although for much of this information the entry is ‘S’ for ‘Special’ for the Lotus.

This information is:

Drive

1 – RHD, 2 – LHD

Eng

always ‘S’ for Lotus

Trans

Always ‘S’ for Lotus

Axle

Always ‘S’ for Lotus

Trim

Always ‘A875’ for Lotus

S.V.C. Ref

Usually blank

Paint Code

Usually BA or BA A for Ermine White

Note that this ‘supplementary information’ does NOT form part of the unique identification of the vehicle. That is, the colour of the car can be changed, and of course, the car can be changed from RHD to LHD, or LHD to RHD, without affecting the identification of the car.

You can see from above that the body code for the Lotus Cortina is 74, which is the code for the Cortina Saloon, 2 door de Luxe – floor change. The Lotus shell was based on that body shell, so you have to be careful that a Vehicle Number with ’74’ in it does not mean it’s a Lotus Cortina!

Although the Lotus Cortina was manufactured at Dagenham, with final assembly at Lotus in Cheshunt, it was a break from the norm for Ford to only partly complete the build of a car. Perhaps they just couldn’t bring themselves to give the Lotus Cortina a unique body Type designation, which had to wait until the Mk2 came along.

For completeness, these are the Body Type Codes that were used for Cortinas:

71 Cortina Saloon (2 door Standard)

72 Cortina Saloon (4 door standard)

73 Cortina Saloon (2 door de Luxe – Column Change)

74 Cortina Saloon (2 door de-Luxe – Floor Change)

75 Cortina Saloon (4 door de Luxe – Column Change)

76 Cortina Saloon (4 door de Luxe – Floor Change)

77 Cortina Saloon (2 door GT)

78 Cortina Saloon (4 door GT)

81 Cortina Saloon (2 door Super – Column Change)

82 Cortina Saloon (2 door Super – Floor Change)

83 Cortina Saloon (4 door Super – Column Change)

84 Cortina Saloon (4 door Super – Floor Change)

86 Cortina Estate (de Luxe – Column Change)

87 Cortina Estate (de-Luxe – Floor Change)

88 Cortina Estate ( Super – Column Change)

89 Cortina Estate (Super – Floor Change)

The Body Tag

There is one more plate that uniquely identifies the Body Shell used in the vehicle, known as the Body Tag. It is a small oblong plate which contains three pieces of information:

- The type of shell (Lotus, GT, Super, Deluxe, Estate)

- RHD or LHD

- The sequence number (within the RHD or LHD group).

For example, a Body Tag with 436 RHD 37 is the 37th Right Hand Drive Lotus Cortina shell built. 436 LHD 342 is the three hundred and forty second left hand drive shell built.

Note that this plate was used for production purposes, and does not form part of the unique identification of the car. As it is riveted on, it can easily be lost in restoration, or swapped over to another shell. There are implications for both scenarios!

PRODUCTION NUMBERS

Trying to establish how many Mk Lotus Cortinas were made has been the subject of many debates, and the total number varies from 2894 to 3304.

The lower number comes from Ford records, and the upper is from a combination of information from the only Lotus record left, the dispatch diary, and the extrapolation of information from the register held by the LCR. This is a combination of Body Code numbers, from the small oblong tag attached to the inner wing, and the chassis numbers, which for the 1965 and 1966 cars ws just a sequential number.

However, there are a few factors to consider that may explain the differences.

Firstly, there were many Service Shells made that wouldn’t have been included in Ford’s figures for cars made. They had a unique ‘Body Code’ just as a completed car did, which would just be the ‘next’ number in the sequence for Lotus Cortinas, with a different sequence number for Right Hand Drive and Left Hand Drive.

Secondly, most Lotus Cortinas had the initial part of the chassis code as ‘Z74’ or ‘BA74’. There were quite a few that had ‘Z85’ or ‘BA85’ instead, and the reason for this difference is unknown. It’s also not known if the Ford lower figure includes the ‘85’ coded cars.

Thirdly, Lotus record keeping can be unreliable. Lotus kept many types of record to convince the authorities that the target for homologation was being met, and to gain tax advantage with creative accounting.

Ford’s records provide interesting reading, if for no other reason than looking at proportion of cars built by year. Their figures are:

1963 – 228 (22.8 per month over 10 months)

1964 – 563 (46.9 per month over 12 months)

1965 – 1112 ( 92.6 per month over 12 months)

1966 – 991 (123.8 per month over 8 months)

Total – 2894

The Lotus dispatch diary that remains shows a different story:

1963 – 707 (70.8 per month over 10 months)

1964 – 569 (47.4 per month over 12 months)

1965 – 1054 ( 87.8 per month over 12 months)

1966 – 974 (121.8 per month over 8 months)

Total – 3304

So which is correct? Nobody knows for sure, but there are some aspects to consider:

Firstly, Ford had the most complete and accurate Production Managment system in the world for car manufacturers in the 1960s. Lotus, well, didn’t.

Secondly, it is well known that Lotus had real issues starting up Cortina production, with very few cars completed in the first few months. They were also starting production of the Elan at the same time, and had very few people to complete both builds.

Thirdly, Lotus were under extreme pressure to get enough Cortinas built for homologation. It wasn’t unknown for them to have two sets of ‘books’ to persuade the authorities they were on track. A cursory examination of the Elan Invoicing book shows that Elan chassis numbers jumped by 3000 in early 1963, for no obvious reason!

Fourthly, a look at the increase in the capability of Lotus to dramatically increase the number of road cars built in one year.

In 1962, Lotus were making two road cars…the Lotus 7 and the Lotus 14 (Elite). We can ignore how many Lotus 7s were built as they carried on making them in 1963, 64 etc. In 1962 some 260 Elites were built.

In 1963 they made a few Elites and 300 Elans, so quite a significant increase on 1962 numbers just on the Lotus cars. And remember that the Elan was all-new design requiring a fair bit of trial and error to build (little production engineering in Lotus then!) and a lot of problems with the Twincam engine for the first few months of production.

Now add in 700 Cortinas being built up, with all the issues around manpower, different processes for building and a huge conflict between how Lotus did things and Ford did things for a few months. That’s 1000 road cars in 1963, compared with 260 in 1962. They had the space to do it (just), but given the extra manpower required, the establishment and settling down of the build process for 2 new cars, the problems with the engine and undoubtedly the supply of the correct parts, such an achievement beggars belief.

Finally, some simple arithmetic. As it is known that Lotus had trouble starting up production of the Lotus Cortina and the Elan at the same time, doesn’t it seem odd that they managed to make more Lotus Cortinas in 1963 than in 1964? When production started (early 1963) the pressure was on to get ‘1000’ cars built for homologation, but it seems likely that as few as 200 – 300 cars may have been made in 1963. Production doubled in 1964, doubled again in 1965 and increased in 1966, probably due to the introduction of the left hand drive (Type IV) model.

Despite the anomalies, the upper figure (rounded) of 3300 cars made seems to be the most accepted one.

There weren’t many left hand drive cars made as they were not available until October 1965, with production starting at the end of August 1965. Some 160 were made for the North American market, with another 60 or so going to Canada. The total number of LHD cars made is around 660, but it is not known which markets, other than the North American market, they were sold to.

The Special Equipment package was made available to give the cars a little extra performance and higher specification equipment. Officially, 68 cars were converted, but of course, considerably more than that had some if not all of the upgrades. It was a nice little earner for Lotus, and as an indication, more than 60% of Elans made were to S/E specification.

One of the main considerations for having an ‘official’ S/E package or not was that the Ford warranty was invalidated by having it! Little wonder that most cars didn’t go the official route but had the modifications done quietly at the workshop in Cheshunt.

It was intended to produce 30 ‘Production Racing’ cars for known racing teams around the world. However, 51 were produced. These cars were very close in specification to the Team Lotus works race cars.

Breaking down the production numbers by type is also a very approximate exercise, especially given the anomalies of the number of cars made. In providing this breakdown, the 3300 total is used, and the analysis has been done by examining chassis numbers, and extrapolating numbers from known change points.

In very round terms:

Pre-Aeroflow cars – 1039

Made up from 10 months in 1963, average 70.8 cars per month. Total 1963 Pre-Aeroflow cars- 708 cars plus

7 months in 1964, average 47.4 cars per month. Total 1964 cars 331

Aeroflow cars – 2265

Made up from 5 months in 1964, average 47.4 cars per month. Total 1964 Aeroflow cars – 237 plus

12 months in 1965, average 87.8 cars per month. Total 1965 Aeroflow cars – 1054 plus

8 months in 1966, average 121.8 cars per month. Total 1966 Aeroflow cars – 974.

A-Frame Cars (covering both Pre-Aeroflow and Aeroflow) – 1986

Made up from total Pre-Aeroflow production – 1039 plus

For Aeroflow cars, 5 months in 1964, average 47.4 cars per month, total 332 plus

7 months in 1965, average 87.8 cars per month. Total 615. Total Aeroflow A Frame 332 + 615 = 947.

Total A Frame cars is 1986 (1039 Pre-Aeroflow + 947 Aeroflow)

Leafspring – 1318

Made up of total Mk1 Lotus Cortina production – 3304 less total A Frame production 1986

However, it is known that leaf spring ‘prototypes’ were started to be built in February 1965 (the KPU cars) and in June 1965 (the GBP Police cars), and that some customer cars were built with leafsprings at Cheshunt before A Frame production officially stopped In August 1965. We will never know those numbers of course, but the number of leafspring cars made could easily be an additional 100 units on the numbers above, with the same reduction in A Frame numbers.